【Hiking Note Column】Intelligent Temperature Control for Functional Fabrics to Deal with Extreme Outdoor Climate Change

Xpore Column / 2022.03.17

Editor’s note:This functional textile encyclopedia column is contributed by “Hiking Notes” and “BenQ Materials Xpore.” We will invite experts from all areas to share the latest textile technologies. The following is an edited oral record from our guest in this episode, Professor Wu Chang-mou, Department of Materials Science and Technology, National Taiwan University of Science and Technology.

▲Photo/Professor Wu Chang-mou

When extreme weather becomes the norm in the future, outdoor clothing should become more intelligent, and combine technology to adjust our body temperature for sufficient protection. When it comes to active intelligent temperature control, most people think electronic textiles will use electronic sensors and heating components to adjust clothing temperature; however, new material technologies can achieve dynamic temperature control without electricity. The focus of this episode is “functional material technology” that can actively control temperatures. They do not need electricity, have long-lasting effects, and are currently the most widely used new generation of intelligent temperature control methods.

1. What is functional material technology?

It means using physical or chemical mechanisms to adjust the temperature on the fabric actively. It can be directly added to the fiber material, post-processed, or directly attached to the functional membrane to achieve temperature control, which are standard technologies used today. The categories of the temperature control mechanism are: “temperature sensing,” “humidity sensing,” and “light sensing.”

- (1) Temperature sensing

Temperature sensing means the fiber material can detect temperature changes and actively adjust them. This technology was developed the earliest and had the most applications. The best known is the “Phase Change Material” (PCM). This material releases or absorbs a large amount of energy when the “phase state changes.” For example, it will absorb heat and turn into a liquid, and it can release heat and become solid. Its conversion process can absorb external temperature changes to achieve temperature regulation. The phase change material can be made into nano-capsules [1] and placed into fibers to cool at high temperatures and heat at low temperatures. Take the Outlast® smart fabric developed by NASA (the National Aeronautics and Space Administration) as an example; it was a patented technology developed for the spacesuit to automatically adjust temperatures in extreme weather conditions to keep astronauts safe. It was widely used in outdoor garments and other applications later.

[1] Recently, there have been applications of embedding phase change material into fibers without nano-capsules. Many small energy storage units are embedded in each fiber, which gives greater energy storage efficiency.

▲Take phase change material – sodium acetate – for example; watch the phase change when it encounters hot/cold (start watching at 20 sec.)

▲Candle material – paraffin – is also a typical phase change material that has a good heat storage capability (Photo/123RF)

Another temperature sensing technology is “shape memory fiber,” which adjusts the shape of its fiber to achieve temperature control when it senses a temperature change. Its principle is like memory metal, where the bent metal can return to its original shape by heating or cooling. “Shape memory polymer materials” fiber has repeated deformation characteristics. For example, it can bulge when it encounters high temperatures to create larger fiber gaps for ventilation and close these gaps when the temperature drops for windproofing and warmth. Actively control the temperature with the function of “shape memory.” (Note: above example is hot bulge/cold flat, but it can also be hot flat/cold bulge, depending on the material properties.)

▲Shape memory fibers bulge when the temperature is hot, increasing the gap between the fibers, and they will flatten and close when cold.

In addition to fiber applications, combining functional membrane and post-processing treatments can also be used for temperature control. Laminating a functional permeable membrane that changes with the temperature opens the membrane pores when the temperature is hot to dissipate heat and moisture, shrinking the pores when the temperature is cold for windproofing and warmth, like a pinecone. Applying a coating of temperature-sensitive post-processing agent on the fabric has the same effect. Although the sensing principle is different, it can also adjust the heat release and cold shrinkage.

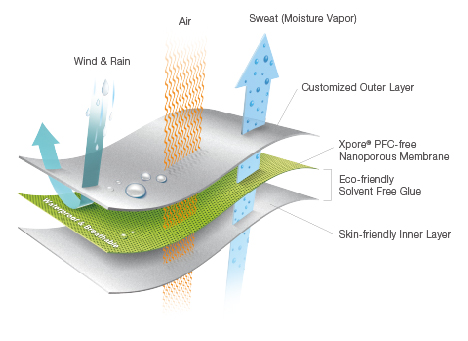

▲Principle of the pinecone effect

The breathable membrane combined with the waterproof function mentioned above is often used on outdoor waterproof jackets. It uses the principle of different diameters of water vapor and water molecules to design a porous membrane to achieve the moisture-permeable and waterproof effect that sweat can get out, but rain can’t get in. Other than outdoor garments, medical clothing also uses this technology. A porous membrane is attached to medical protective clothing to prevent infection-causing blood and droplets from entering the inner layer, and it’s breathable so the medical staffs’ sweat can discharge and they feel more comfortable during their activities.

▲The principle of waterproof and moisture-permeable porous membrane diagram

- (2) Humidity sensing

This means the fiber can sense the humidity change and actively adjust to it. This material can open and close like a sponge will expand or contract when it absorbs water. Humidity sensing fabrics absorb water and open the pores between the fibers to dissipate moisture and sweat when they encounter humidity. The fiber will stretch and close the pores to be windproof and keep warm in a dry place. The human body is a very sensitive sensor. We feel discomfort when the humidity is high, even at the same temperature. Humidity can take away body heat, so keeping the body dry is vital for the fabric.

▲After the moisture sensing fiber absorbs moisture, the fiber pores will automatically expand to dissipate moisture, and when the water evaporates, and the fiber dries, the pores will automatically close.

▲Explanation of the humidity sensing fiber principle (start watching at 20 sec.)

In addition to overall humidity sensing fiber, the Taiwan Textile Institute also introduced technology for local post-processing. The method is to apply the moisture sensing agent to heavy sweating areas (like armpits or the back) by digital printing to emphasize the moisture dissipation functionality. Besides the functionality of this technology, it’s also for aesthetics, such as designing unique patterns that will only show when wet. Hence, the garment has a more interesting visual effect during exercise.

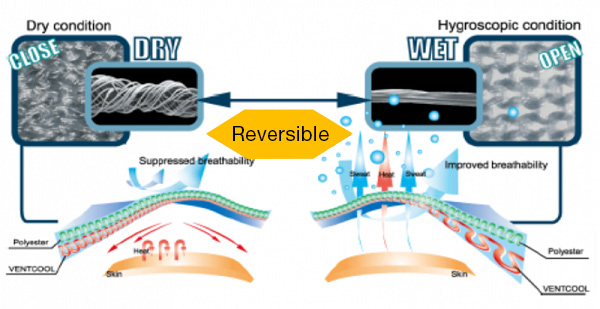

Manufacturers are imitating the wool and combining hydrophilic and weak hydrophilic fibers so that the two sides of a fiber (Side by Side) have different characteristics. When this type of fiber encounters moisture, one side will absorb water and swell, and the other will remain unchanged. The difference in density or stretchability of the two sides produces a bending effect, increasing or reducing the holes between the fibers to achieve air circulation or windproofing.

▲Composite fiber – VENTCool moisture sensing fiber transformation. The fiber naturally curls when dry, making the fabric pores small to reduce air permeability; when wet, it will stretch temporarily to improve air permeability (Photo/TLC)

- (3) Light sensing

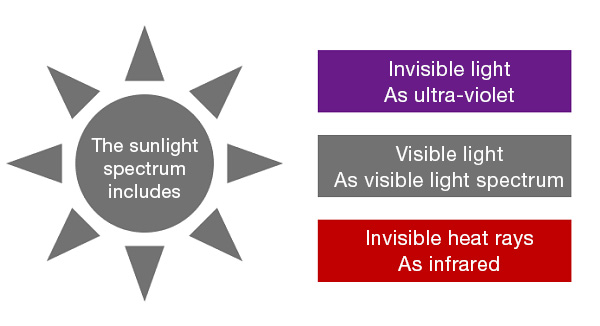

It means the fiber can sense the light change and actively adjust it. For example, sunlight makes people feel hot because of the infrared. If the fabric can reflect infrared, it won’t penetrate the inner layers and reduce the temperature. The standard method to reflect heat is to add titanium dioxide and other organic metal materials in the fiber to reflect infrared physically; on the other hand, we can make it absorb infrared to generate heat.

▲“Invisible heat rays” in sunlight – infrared is the heat source

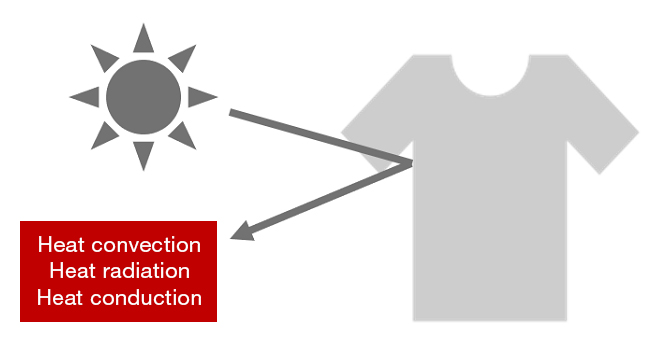

▲Sun-blocking textiles can isolate infrared heat convection, heat radiation, and heat conduction

2. Other intelligent temperature control technology

Intelligent textiles don’t have a large volume in the outdoor garment market, but their application for extreme temperature plays a more critical role in specific areas. For example, a chip installed in a firefighter’s jacket can detect the body’s temperature and outside. Once the temperature exceeds a specific number, the “cooling chip” will quickly activate and reduce the jacket temperature. In the same way, the heating components can turn on to allow outdoor athletes to gain warmth in a low-temperature environment, reducing the risk of hypothermia, which will be greatly helpful in high altitudes or polar expeditions.

▲You can turn on the heating components in the intelligent electronic textiles to allow outdoor athletes to be warm in a low-temperature environment (Photo/123RF).

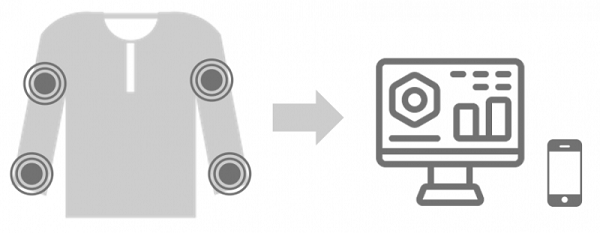

Besides detecting temperatures, the intelligent electronic textile can also be used in form-fitting undergarments to correct exercise forms. For example, install sensors on the arm and armpit areas of the garment to collect exercise data during athletes’ movements; then transfer the data to digital platforms (website or an App) to check the difference between the actual angle and the recommended angle of exercise. This way, we can improve the athletes’ effectiveness and reduce injuries.

▲install sensors on the arm and armpit areas of the garment to collect exercise data, then transfer the data to digital platforms

Unlike the functional material technology that can achieve temperature control by physical/chemical reaction, the challenge of electronic textile lies in the continuity of electricity. Therefore, solving the problem of electricity consumption is one of the research focuses of electronic textiles. Instead of using batteries, the use of piezoelectric materials (e.g. the power plate placed on the sole of the shoe to generate electricity through the movement of the shoe) and friction are solutions to actively generating electricity. The power density is still low and can only supply power to the sensors than to independently support power generation. No matter what technology we use, intelligent temperature control is vital for dealing with extreme climates. It can reduce the impact of the human body on external environments. And not only in outdoor sports – this will become an essential design concept for all clothing in the future.

Interviewee

Professor Wu Chang-mou, Department of Materials Science and Technology, National Taiwan University of Science and Technology.

Enjoy outdoor sports such as cycling and badminton. Encourages students to get close to mother nature. He has completed all sorts of fun adventures with his students like cycling the South Island, snorkeling, and river tracing.

Sustainability Fabrics Encyclopedia

Xpore® core technology is a unique ultra-thin membrane with 10 billion nanopores per square inch. These pores are 20,000 times smaller than a water droplet, extremely wind- and water-resistant, and at the same time, large enough to allow sweat to pass through. Truly breathable nanopores can let users exercise longer and keep them dry and comfortable.

Source: (Chinese) https://hiking.biji.co/index.php?q=news&act=info&id=21031

Interested in Intelligent Temperature Control Jacket? Check this sustainable smart outdoor jacket from PYKRS!