- HomeSustainabilityForum

From Material Science to Mission: 2025 Cross-Industry Circular Economy Forum

As the global community accelerates toward net zero and sustainable transformation, BenQ Materials and its functional textile brand Xpore is honored to host the From Material Science to Mission: 2025 Cross-Industry Circular Economy & Sustainability Forum on September 16, 2025.

With a focus on ESG, circular economy, and responsible supply chains, the forum brings together international brands, industry leaders, and research institutions to discuss how cross-industry collaboration can drive sustainable innovation and position “Taiwan Sustainable Manufacturing” as a trusted global mark.

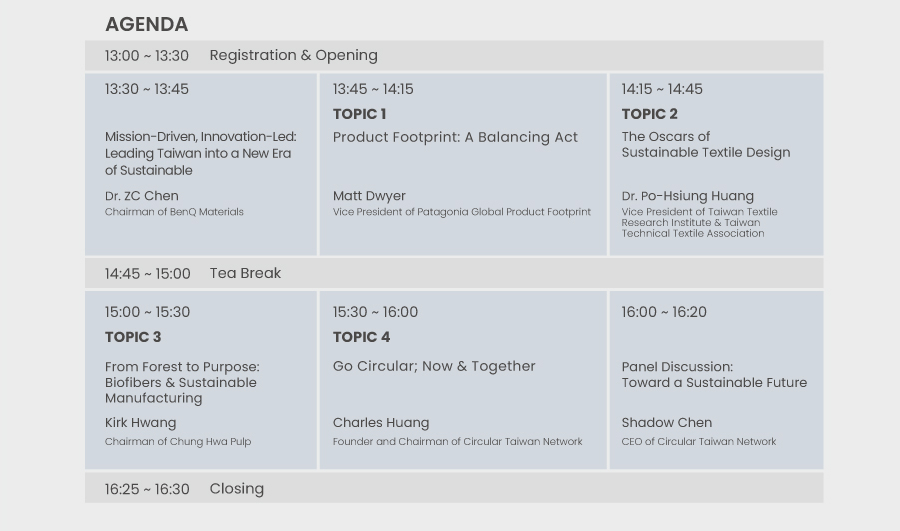

Taipei, September 16, 2025 – BenQ Materials hosted the groundbreaking “From Material Science to Mission: 2025 Cross-Industry Circular Economy Forum” at the Taiwan Textile Research Institute today. This milestone event gathered global brand Patagonia, the Taiwan Technical Textiles Association, Chung Hwa Pulp Corporation, and the Circular Taiwan Network to explore how material innovation, product footprint, responsible supply chains, and cross-industry collaboration can advance sustainable transformation. The collective goal: to position “Sustainable Manufacturing in Taiwan” as a trusted global hallmark.

BenQ Materials: Cross-Industry Vision and Leadership

Dr. ZC Chen, Chairman of BenQ Materials, opened the forum by emphasizing that enterprises should not merely serve as suppliers, but as “co-creators of sustainable value.” Expanding from electronics into textiles, BenQ Materials is driving cross-industry circularity through its performance textile brand Xpore. The pioneering Xpore e2cycle – the world’s first and only recycled PET fabric derived from LCD waste – demonstrates how e-waste can be transformed into high-performance, durable, and functional textiles. This innovation connects the electronics and textile sectors, realizing the vision of “upcycling and upvaluing” materials to prolong their lifecycle and boost value.

Patagonia: Sustainability DNA and Collaborative Action

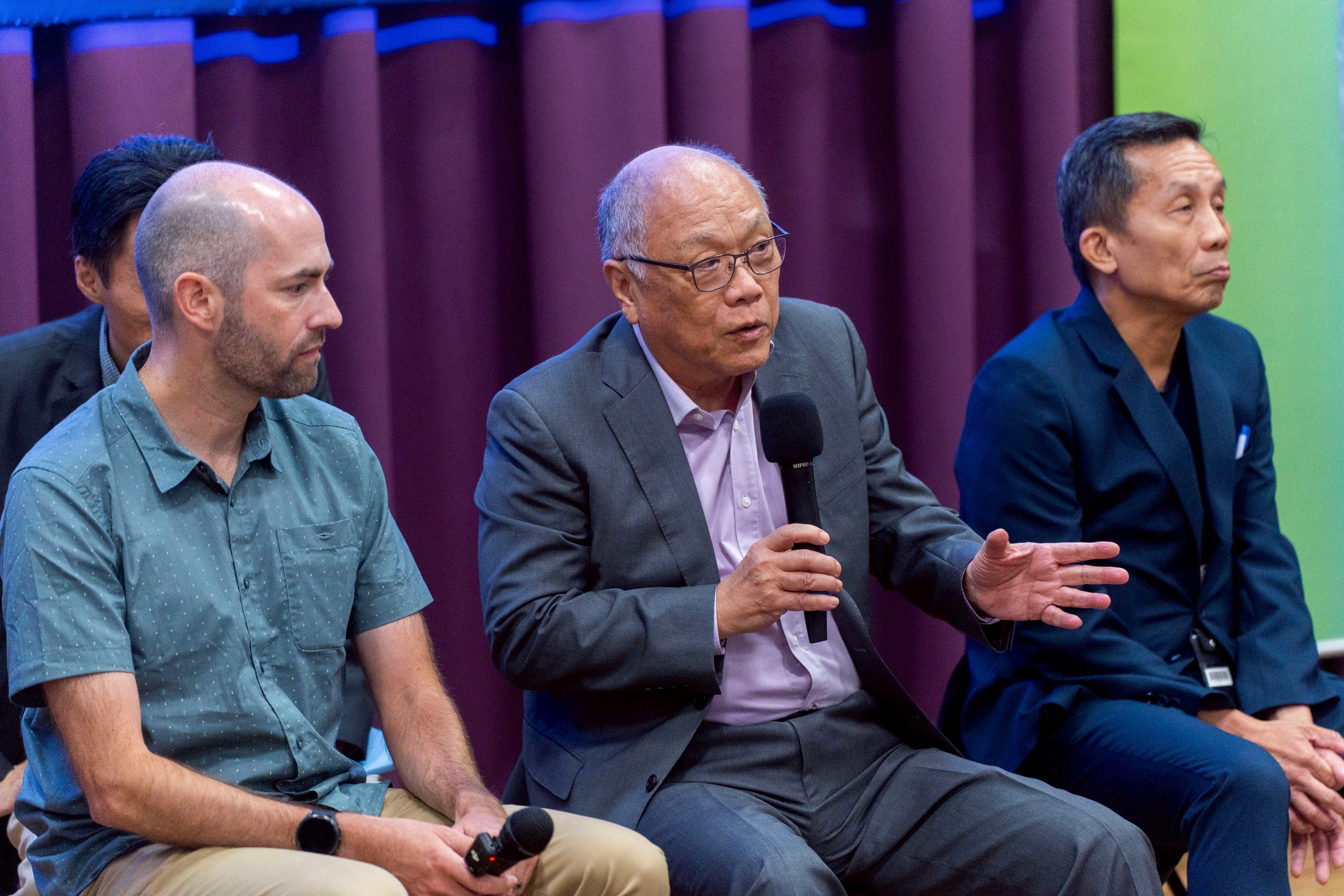

Matt Dwyer, Vice President of Global Product Footprint at Patagonia, delivered a keynote titled “Product Footprint: A Balancing Act,” reviewing a decade of progress and challenges in implementing preferred materials – fibers and raw materials that improve environmental or social sustainability outcomes, now used in over 95% of Patagonia’s products. Dwyer underscored Patagonia’s pledge to eliminate PFAS by 2025 and to push the “Waste Economy,” such as transforming discarded fishing nets into NetPlus® nylon, diverting over 6.2 million pounds of ocean-bound nets since 2018. He highlighted the company’s “Fair Trade” initiatives, showing with data how these raise employee satisfaction, enhance product responsibility, and build consumer trust, while moving toward the “living wage” goal.

Xpore and Patagonia: Opportunities and Challenges in Partnership

Dwyer spotlighted the journey of collaboration with Xpore: from rigorous audits to enduring partnership, Patagonia recognized the potential of Taiwanese suppliers in the global chain. When Xpore debuted in 2020 with its PFAS-free, solvent-free material, Patagonia quickly initiated discussions in pursuit of high-performance yet eco-friendly solutions.

The real test came with Patagonia’s thorough audits in 2023, examining wages, safety, worker welfare, and even conducting direct interviews with frontline staff. Xpore’s transparent pay practices, above-standard benefits, and honest culture enabled it to pass in one attempt—often a rare feat among textile factories. This transparency and commitment accelerated the partnership and deepened mutual trust.

Today, Xpore and Patagonia have moved beyond a traditional client–supplier model, becoming true problem-solving partners. Xpore’s highest-grade Ultra nanoporous film is now featured in the Patagonia M10® Waterproof Alpine Anorak, designed to withstand extreme environments with outstanding performance and comfort—all through a PFAS-free process that exemplifies the best in technological and sustainable innovation.

Xpore’s story demonstrates that Taiwan’s textile industry can not only match global standards in technology, but also excel in ESG, supply chain responsibility, human rights, and transparency—offering a blueprint for how material science can be mission-driven and setting a new bar for sustainable transformation.

Textile Association: Innovation Through Design

Dr. Cam Huang, Secretary-General of the Taiwan Technical Textiles Association, shared stories of "the Oscars of the textile world,” highlighting the industry’s dual strengths in high-performance and sustainable design, and urging more companies to make sustainability the core of brand value.

Chung Hwa Pulp: From Forest to Future Materials

Kirk Hwang, Chairman of Chung Hwa Pulp Corporation, spoke on “From Forest to Purpose,” demonstrating commitment to responsible forestry and circular manufacturing. By expanding pulp into biofibers and low-carbon packaging, coupled with energy transformation, Chung Hwa Pulp aims for 50% green energy self-sufficiency by 2030, embodying sustainable innovation in raw materials.

Circular Taiwan Network:Good Idea+ Good Governance = Good Business

Charles Huang, Chairman of the Circular Taiwan Network, called for breaking linear thinking and advancing Circular Collaboration for Climate Crisis (CC4CC). Only through cross-industry and international cooperation can a sustainable ecosystem be built, citing the limited impact of global carbon reduction efforts over the past 30 years .

With its purpose-driven approach and focus on material innovation, BenQ Materials aims to lead Taiwan into a new era of sustainable manufacturing. From global brand Patagonia to Taiwanese leaders in material science, textiles, and circular industries, all participants echoed the call to establish the “Taiwan Can Lead” alliance. By integrating ESG, circular economy, and responsible supply chains, they aspire to make “Sustainable Manufacturing in Taiwan” a global standard and to propel cross-industry transformation toward a sustainable future.

Speakers

As the host of this year’s forum, BenQ Materials is honored to convene international brands, industry leaders, and research institutions to discuss how cross-industry collaboration can accelerate sustainable transformation.

At BenQ Materials, we believe sustainability requires more than innovation — it requires alliances. With Xpore, our low-impact material innovation brand, we are proud to initiate the Cross-Industry Circular Economy Alliance (CICEA), bringing together electronics, textiles, brands, and associations to:

From Materials Science to Mission

Drive material innovation and cross-sector collaboration

Build responsible and transparent supply chains

We are honored to welcome Matthew Dwyer, VP of Product Footprint at Patagonia, as one of our keynote speakers. Patagonia has long been recognized as a global leader in sustainability, and at this forum, he will share insights under the theme:

Topic 1 – Product Footprint: A Balancing Act

✨ Key highlights include:

· 10 Years of Progress (and Some Failures) in adopting Preferred Materials

· Transitioning Away from PFAS to reduce environmental and health impacts

· The Future of the Waste Economy and new models for circularity

· Opportunities and Challenges of Partnering with Xpore to drive material innovation and sustainability

This session will set the stage for how cross-industry collaboration can redefine the future of sustainable manufacturing and position Taiwan as a trusted global mark.

We are excited to welcome Dr. Po-Hsiung Huang, VP President of the Taiwan Textile Research Institute and General Secretary of the Taiwan Technical Textiles Association, as a featured speaker. He will share insights under the theme:

Topic 2 – The Oscars of Sustainable Textile Design

✨ Key highlights include:

-How the “Oscars” of global industries — R&D 100, Edison Awards, and iF Design Award — inspire the textile industry’s path toward sustainability

-Showcasing international award-winning cases in sustainable materials, processes, and circular innovation that can shape the future of Taiwan’s textile sector

This session will highlight how design and innovation play a pivotal role in advancing the textile industry toward sustainability.

We are honored to welcome Mr. Kirk Hwang, Chairman of Chung Hwa Pulp, as one of our featured speakers. His session will address:

Topic 3 – From Forest to Purpose: Biofibers and Sustainable Manufacturing

Key highlights include:

· Responsible forest management & circular operations: treating forests as renewable assets

· Biofiber innovation: spinning pulp into saccharide-based fibers as low-carbon alternatives to cotton and rayon

· Circular packaging: developing pulp-based packaging solutions with lower carbon intensity

· Energy transition: achieving 1/3 in-house green power today, and targeting 50% zero-carbon self-sufficiency by 2030

This presentation will highlight how pulp can evolve beyond traditional use to become a platform for sustainable manufacturing, renewable energy, and next-generation materials.

We are delighted to welcome Mr. Charles Huang, Chairman of the Circular Taiwan Network, as one of our distinguished speakers. He will share insights under the theme:

Topic 4 – Go Circular; Now & Together

Key highlights include:

· Beyond Green to Circular: moving past traditional sustainability to embrace systemic change

· Beyond Linear: reversing 30 years of limited progress in global carbon reduction through circular practices

· Beyond Material Flows: restructuring supply chains into networks of circular products and services, advancing CC4CC (Circular Collaboration for Climate Crisis)

This session will emphasize why collaboration and systemic circularity are essential for Taiwan to strengthen its global role in sustainable manufacturing.

Watch Session Recordings

Related Articles

- Xpore Column2025.08.29

- From Material Science to Mission: Cross-Industry Circular Economy & Sustainability Forum 2025

- Xpore Column2025.07.24

- Solar-powered. Self-certified. 100% clean electricity.

- Xpore Column2025.07.21

- Why PFAS-Free Waterproof Membranes Matter

- Product2025.05.29

- Xpore e2cycle Wins Dual Honors at 2025 FIT Sport Design Awards

- Exhibition2025.04.15

- Where Displays Meet Textiles – Xpore Debuts e2cycle at Touch Taiwan 2025

- Exhibition2025.02.04

- Xpore at Performance Days 2025

.jpg)