從材料科學到使命:2025 跨域循環經濟論壇

隨著全球社會加速邁向淨零排放及永續轉型,明基材料及其旗下功能性紡織品牌Xpore榮幸地於2025年9月16日主辦「從材料科學到使命:2025跨產業循環經濟與永續論壇」。

本次論壇將聚焦ESG、循環經濟和負責任供應鏈,匯聚國際品牌、產業領袖和研究機構,共同探討如何透過跨產業合作推動永續創新,並將「台灣永續製造」打造為值得信賴的全球標誌。

明基材料(BenQ Materials)於9/16假台灣紡織產業綜合研究所舉辦「從材料科學到使命:2025 跨域循環經濟論壇」。此次論壇集結國際品牌Patagonia、台灣產業用紡織品協會、中華紙漿、循環台灣基金會等跨界領袖,共同探討如何透過材料創新、產品足跡(Product Footprint)、責任供應鏈以及跨產業合作推動永續轉型,並攜手將「台灣永續製造」打造成全球信賴的標誌。

明基材料:跨域合作與品牌願景

明基材料董事長陳建志在開場致詞中指出,企業不應僅是供應商,更應成為「永續價值的共同創造者」。從電子跨足紡織,明基材料以旗下機能織物品牌 Xpore 為起點,推動跨域循環經濟,並透過目前全球唯一來自 LCD 廢棄物的再生 PET 織物的 Xpore e2cycle ,該創新技術能將電子廢棄物轉化為高性能機能紡織品,兼具耐用性與功能性,技術建立電子業 × 紡織業的新模式,實現 Upcycle 與 Upvalue願景,讓材料延展生命並提升價值。

Patagonia:永續 DNA 與合作實踐

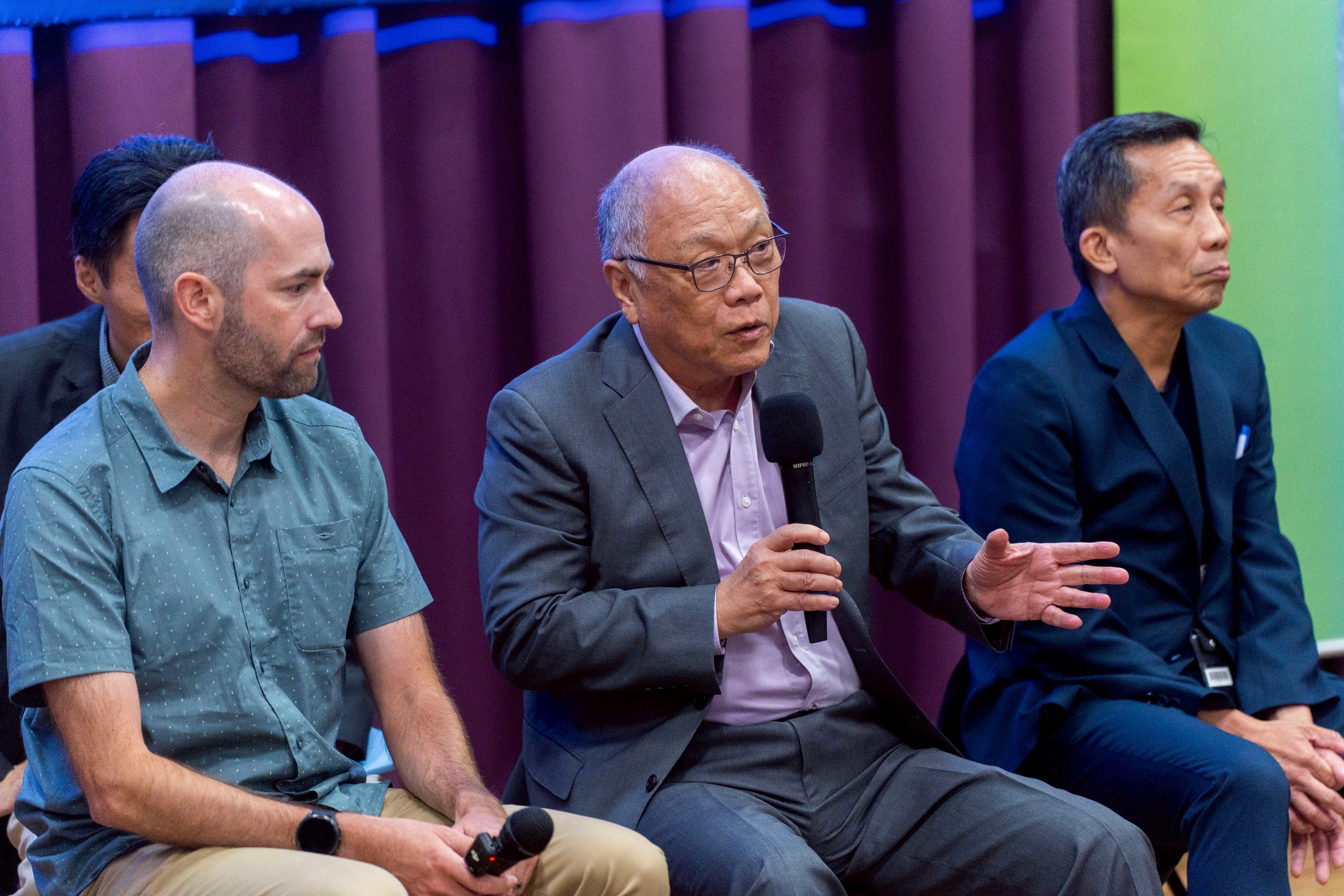

Patagonia 全球產品足跡副總裁 Matt Dwyer 則以「產品足跡:平衡的藝術 Product Footprint: A Balancing Act」為題,回顧十年來在推動首選永續材料(Preferred Materials, 可改善環境或社會永續成果的纖維或原材料)上的進展與挑戰,目前產品已達95%以上採用率。他強調,Patagonia 承諾在 2025 年全面淘汰 PFAS(全氟化合物),並持續發展 Waste Economy,例如以回收漁網製成 NetPlus® 尼龍,從2018s年至今,已轉化超過 620 萬磅漁網,減少海洋廢棄物,同時,除了環境永續更加強調企業推動「公平貿易 Fair Trade」計畫對於員工、產品及整體社會帶來的正面影響,並以數據佐證其持續邁向「生活工資」(Living Wage)目標的成果。 整體資料突顯,企業不僅透過公平貿易認證提升供應鏈責任與產品形象,這一系列數據與制度設計有助於提升員工滿意度、品牌價值以及消費者信任。

Xpore與Patagonia合作的契機與挑戰

Dwyer 特別提及與 Xpore 的合作故事:從嚴格的稽核挑戰到最終的長期合作,Patagonia 看見台灣企業在國際供應鏈中的潛力。故事要追溯到2020 年,Xpore 正式推出,帶著「無氟(PFAS-free)、無溶劑(solvent-free)」的創新材料進入市場。這樣的定位,正好呼應了 Patagonia 長期以來尋找更環保材料的需求。當 Patagonia 的創新團隊注意到 Xpore 時,立即展開接觸,期待能找到符合性能、同時減輕環境負擔的新選項。

技術只是第一步,真正的考驗來自 Patagonia 對社會責任與人權的稽核。2023 年Patagonia 稽核團隊進駐工廠,逐項檢視薪資、工安、勞工福利,甚至與基層員工一對一面談。這對許多紡織廠而言是難以跨越的高牆,但 Xpore 依靠透明薪資制度、優於勞基法的福利,以及誠實對待員工的文化,順利一次通過稽核。這不僅大幅加快合作進程,也奠定了雙方的深厚互信。

經過這段歷程,Xpore 與 Patagonia 的關係已超越傳統「客戶 – 供應商」模式,成為並肩解決問題的合作夥伴。Patagonia 看重的不只是材料性能,更是與Xpore 共同推動地球永續的價值觀,進而合作推出 Patagonia M10® Waterproof Alpine Anorak 輕量三層防水外套,就是採用 Xpore 最高階 Ultra 奈米多孔薄膜,能承受極端環境,具備卓越性能與舒適度,無氟製程更展現了科技 × 永續的最佳典範。

Xpore 的成功故事,證明台灣紡織業不僅能在技術創新上與國際品牌接軌,更能在 ESG、責任供應鏈、人權與透明度上與世界最高標準比肩。這段合作歷程,正是台灣產業如何從材料科學走向使命驅動的最佳寫照,也為紡織業樹立了永續轉型的新榜樣。

紡織產業協會:設計驅動的永續創新

台灣產業用紡織品協會秘書長黃博雄分享「紡織界的三大奧斯卡」案例,展現台灣紡織業在高性能與永續設計的優勢,並呼籲更多業者將永續視為品牌價值的核心。

中華紙漿:從森林到未來材料

中華紙漿董事長黃鯤雄 以「From Forest to Purpose」為題,闡述如何透過責任林業管理與循環製程,將紙漿應用擴展至生物纖維與低碳包裝材料,並結合能源轉型,目標在 2030 年達到 50% 綠能自給,展現原物料產業永續創新的決心。

循環台灣基金會:Good Idea+ Good Governance = Good Business

循環台灣基金會董事長黃育徵以「Go Circular; Now & Together」為題,指出過去 30 年全球減碳成效有限,唯有超越線性思維,推動 CC4CC(Circular Collaboration for Climate Crisis),才能透過跨產業、跨國界合作,共同打造永續生態系。

本次論壇以「使命驅動,材料創新」為初衷,主辦單位明基材料亦自許未來引領台灣邁向永續製造新時代,從國際品牌 Patagonia,到台灣材料科學、跨界紡織與循環產業的共同願景。與會者一致呼籲成立「Taiwan Can Lead 紡織台灣隊」,結合 ESG、循環經濟與責任供應鏈的力量,將「台灣永續製造」打造成可信賴的全球標誌,並引領跨產業邁向永續未來。

Speakers

使命驅動,材料創新:引領台灣邁向永續新時代

作為今年論壇的主辦單位,明基材料很榮幸能夠匯聚國際品牌、產業領袖與研究機構,共同探討跨產業合作如何加速永續轉型。

在明基材料,我們相信永續不僅需要創新,更需要聯盟。透過我們的低衝擊材料創新品牌 Xpore,我們自豪地發起「跨產業循環經濟聯盟」(CICEA),串聯電子、紡織、品牌與協會,共同推動:

✨ 從材料科學到使命

♦ 推動材料創新與跨領域合作

♦ 建構負責任且透明的供應鏈

我們非常榮幸邀請到 Patagonia 全球產品足跡副總裁 Matthew Dwyer 擔任論壇主講人之一。Patagonia 長期以來被視為全球永續發展的領導品牌,在本次論壇中,他將以以下主題分享深刻見解:

主題一 – 產品足跡:平衡的藝術

✨ 精彩重點包括:

♦ 採用優選材料十年來的進展與挑戰

♦ 從 PFAS 轉型,降低對環境與健康的衝擊

♦ 資源循環經濟的未來與創新模式

♦ 與 Xpore 攜手推動材料創新與永續發展的機會與挑戰

這場演講將揭示跨產業合作如何重新定義永續製造的未來,並強化台灣作為全球信賴標誌的地位。

我們很榮幸邀請到紡織產業綜合研究所協理、同時兼任台灣產業用紡織品協會秘書長的黃博雄博士擔任本次論壇的重量級講者。他將針對以下主題分享專業觀點:

主題二 – 永續設計:紡織界的奧斯卡

✨ 精彩重點包括:

♦ 全球產業界的「奧斯卡」——R&D 100、愛迪生獎(Edison Awards)、iF 設計獎如何啟發紡織產業邁向永續之路

♦ 永續材料、製程與循環創新的國際得獎案例,如何為台灣紡織產業開啟未來藍圖

這場演講將突顯設計與創新在推動紡織產業邁向永續轉型中的關鍵角色。

我們非常榮幸邀請到中華紙漿股份有限公司董事長黃鯤雄先生擔任本次論壇的重量級講者之一。

他將以以下主題進行分享:

主題三 – 從森林到使命:生物纖維與永續製造的未來

✨ 精彩重點包括:

♦ 責任林業與循環運作:將森林視為可再生資產

♦ 生物纖維創新:將紙漿轉化為以醣基為基礎的纖維,作為棉花與人造絲的低碳替代方案

♦ 循環包裝:開發以紙漿為基礎的包裝解決方案,降低碳排放強度

♦ 能源轉型:目前已達成三分之一的自發綠電,並以 2030 年實現 50% 零碳自給為目標

這場演講將展現紙漿如何突破傳統用途,進一步發展為永續製造、再生能源與前瞻材料的平台。

我們很榮幸邀請到資源循環台灣基金會董事長黃育徵先生擔任本次論壇的重量級講者之一。他將對以下主題分享見解:

主題四 – Go Circular; Now & Together

✨ 精彩重點包括:

♦ 超越綠色,邁向循環:突破傳統永續思維,擁抱系統性轉型

♦ 超越線性:透過循環實踐,扭轉過去30年全球減碳有限進展的困境

♦ 超越物質流:將供應鏈重構為循環產品與服務的網絡,推動CC4CC(Circular Collaboration for Climate Crisis)

本場演講強調,唯有透過協作與系統化的循環模式,台灣才能進一步鞏固並提升其在全球永續製造中的關鍵地位。

觀看議程錄影檔

延伸閱讀

- Xpore專欄2025.08.29

- 從材料到使命 — 跨域循環經濟聯盟:解構永續,共創責任未來論壇

- 展覽資訊2025.09.11

- 全球唯一來自LCD廢棄物的再生織物「e2cycle」 首度於亞太永續博覽會亮相,明基材料Xpore實踐跨產業循環經濟

- Xpore專欄2025.07.24

- Xpore 完成 RE100 目標,全面採用自發綠電!

- 展覽資訊2025.04.15

- Xpore 首度參展 Touch Taiwan,e2cycle 引領機能紡織材料跨界創新

- 產品資訊2024.11.27

- Xpore e2cycle 技術榮獲 ISPO Textrends Top 10 大獎!

- Xpore專欄2024.11.19

- 碳競爭力2024光電業第一!明基材如何把垃圾變高價機能衣?

.jpg)